What Is Crushed Rock and Why It’s Essential for Large-Scale Projects

Crushed rock, popularly known as “crushed stone,” is a term that defines a stone that comprises a mix of stone dust. Crushed stone is the most suitable base material in construction projects that need heavy compaction. As a result, crushed rock or crushed stone is suitable for the base of concrete, foundation of driveway bases, and paving projects.

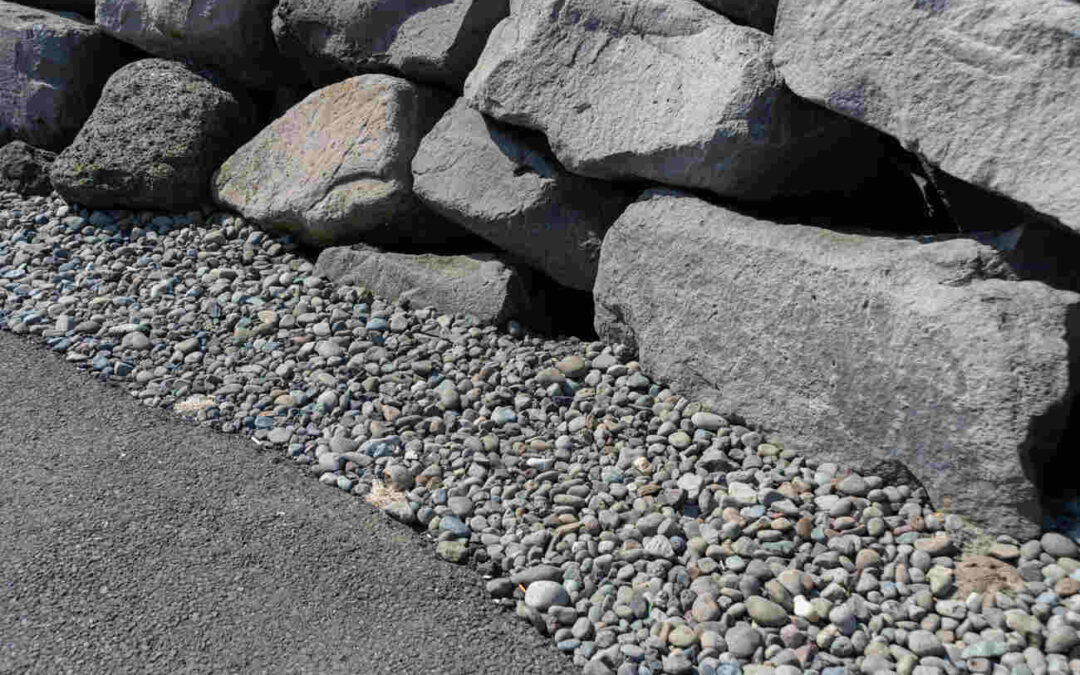

Crushed stone and gravel differ in size and shape. Crushed stone is larger and features rough, jagged edges. Gravel is typically smaller and naturally rounded, hence its soft and aesthetic appearance.

Crushed stone comes in various colors as a result of minerals found in parent rocks, while gravel generally features lighter, earthy hues of brown, tan, or gray.

Common Rock Types Used for Crushing

- Granite: Granite is dense, hard, and durable. It comes in different colors, from deep reds to light gray. It is most suitable for decorative landscaping.

- Limestone: Limestone comprises primarily calcium carbonate. It comes in shades of white, gray, or tan, and its smooth or rough textures ensure that it has a variety of applications.

Crushed rock or crushed stone is preferred as a construction rock for its structural integrity and compaction. Crushed stone is also versatile, and its diverse origins contribute to its wide range of colors, sizes, and textures.

Crushed stone is made by breaking down rocks into smaller pieces, and the crushing machinery results in angular and rough-edged products. The angular edges and roughness of crushed rock offer excellent compaction and interlocking capabilities.

Core Applications: From Road Material to Utility Infrastructure

Crushed-rock aggregates form mortar, concrete, or asphalt when they are appropriately mixed with water and binding agents like cement or bitumen. In their very nature, crushed-rock aggregates are granular filler materials, like sand, gravel, crushed stone, and stone dust.

Crushed stone is a critical road material because it is known to create a stable foundation that can withstand heavy traffic. Crushed rock also has angular shapes that offer superior stability and drainage capabilities, making it suitable as gravel for roads and base rocks.

Crushed rocks are also used in the construction of:

- Drainage and septic systems

- Landscaping

- Pathways and parkways

- Driveways

Base Rock vs. Gravel for Roads

Crushed rock stands out for its outstanding durability. It is produced by crushing hard rock and screening it to achieve the right shape and size, which is usually angular. These angular shapes interlock and provide a stable surface that does not shift under load.

Crushed rock is resistant to weathering, erosion, and environmental wear, which is why it is the first choice as a road material in heavy-traffic areas. Crushed rock is the ultimate durable choice and it compacts better than gravel, making it better than gravel.

On the other hand, gravel is the ultimate easy maintenance choice. Gravel is not as durable as crushed stone, and it does not interlock in the same way as crushed rock. Gravel achieves its natural roundness and smoothness from the action of river water or oceans, and that roundness is what causes it to shift out of position.

Crushed rocks are used in large-volume scenarios, like in the construction of industrial pads and highways. Crushed rock is used as a capping layer when lower-grade aggregate is incorporated over weak soils. It also serves as the main support layer in highway construction when good-quality aggregate is used to create a stiff foundation.

Crushed Rock for Drainage Solutions and Erosion Control

Angular crushed rock is also used to solve drainage issues and for erosion control. Crushed stone is a durable and longer-lasting drainage aggregate that is resistant to erosion. Crushed stone that comes in sizes ranging from 6 mm to 20 mm is used in different drainage applications.

Pea gravel is a smaller, smoother stone that also works well in different drainage applications. As the name suggests, pea gravel is found in sizes ranging from 10 mm to 20 mm, which makes it suitable for surface drainage systems like walkways, driveways, and drainage swales.

Recycled aggregate rocks are an eco-friendly option, and they are a good way to save on the cost of sourcing aggregate rock from quarries. With sizes ranging from 10 mm to 20 mm, recycled aggregate rocks are used in pipe bedding.

Aggregate rocks typically form the main material in the construction of French drains. They allow better water flow, which prevents clogging that is commonly associated with rounded pea gravel. French drains feature aggregate rocks measuring between 20 mm and 40 mm. The angular crushed stones in a French drain also allow for better water flow, which reduces the chances of shifting or settling.

Using crushed rocks for drainage solutions requires adherence to some engineering standards, such as using specific types, sizes, and placement of crushed rocks to ensure effective management of water flow.

Other key engineering considerations include the need for:

- Proper compaction

- Size distribution

- Limited clogging

The Difference in Our Material: Quality, Volume, and Consistency

At Roblar Quarry, we are committed to excellence that is exemplified through rigorous quality assessment and monitoring conducted in our in-house lab. The proactive testing of each aggregate product, such as aggregate rock, crushed rock, and base rock, guarantees product quality, consistency, and volume, and the consistent gradation and material integrity give customers much-needed peace of mind.

Material certification considers various factors, such as the safety, sustainability, and quality of construction products. Our materials have been vetted thoroughly and optimized for various construction applications. Our team of experts constantly analyzes and refines the company’s processes to ensure that it delivers not just aggregate rocks, base rocks, and crushed rock to its customers but also unmatched reliability and value for every project they undertake.

With more than 20 years of experience, Roblar Quarry has sufficient volume capacity for major construction projects. We have undeniable scalability, which refers to the company’s ability to handle increased workloads and larger projects.

Why Contractors Choose Us for Bulk Rock Supply

Roblar Quarry is synonymous with bulk rock supply and construction rock, and for good reason.

- Turnaround time: We provide dependable, on-time delivery of materials to help keep projects moving without delays.

- Delivery reliability: We are a reliable supplier, thanks to our efficient delivery systems that ensure all rocks are delivered to the customer’s site on time.

- Supplier relationships: We have strong supplier relationships with our customers, which stem from years of consistent delivery of quality products, delivery reliability, and fair pricing.

Communication During Bidding and Change Orders

Supply processes undergo various changes, such as a change of orders from customers that must reach the company before an order is processed and concluded. We pride ourselves on effective communication that occurs during bidding and in the event that there is a change in orders. Our effective communication system ensures that communication lines remain open and prompt in order to ensure that a customer’s needs are understood and met without errors.

Roblar Quarry is the trusted partner for crushed rock. We are an experienced and industry-leading provider of crushed rock and other building materials throughout California. Since 2003, Roblar Quarry has served contractors, masonry professionals, landscape designers, and DIYers who continue to rely on the company for quality, extensive inventory, competitive prices, and reliable crushed rock.